Cornell robotics engineer Hod Lipson says 3-D food printing will give home cooks revolutionary new options for convenience, customization.

By Lisa Palmer, Printed with permission from FutureFood 2050, an initiative of the Institute of Food Technologists

The days of multiple kitchen appliances jostling for a share of counter space may be on the wane, if robotics engineer Hod Lipson has his way.

Instead, the countertop array of kitchen appliances could be reduced to one all-purpose machine: a home-size 3-D printer that stacks food ingredients layer upon layer, with precise directions from a design file that dictates how the printer jet will deposit each ingredient. Think bread machine. Only bigger. And smarter.

“You pop in basic ingredients, or frozen ingredients, into a printer, download the recipe from online, and hit print,” says Lipson, director of Cornell University’s Creative Machines Lab, whose team created the first food 3-D printer about a decade ago. “The machine will create your food for you.”

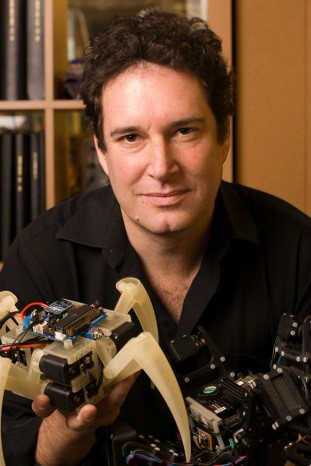

Hod Lipson |

“I think what food printing offers is a way to combine information technology software and biometrics with cooking in a way that was never possible before,” says Lipson.

With 3-D printing still in its infancy and food printing just in the gestational stage, it will likely be a few more years before Lipson’s vision is reality. But a handful of companies are already producing commercially available machines that can print food. ChefJet, which can print in sugar, [was] expected to release its models for between $5,000 and $10,000 by the end of 2014. Barcelona, Spain-based Natural Machines, aimed at the “natural” food consumer, [was] also planning to launch its Foodini for $1,300 by the end of 2014, with mass production available in early 2015. More sophisticated home versions are about two to five years away from commercialization, says Lipson, and in the future he expects people will be able to buy prefilled cartridges of food ingredients (much like [single-brew coffee] beverage capsules), or fill cartridges with their own ingredients like pesto and soft cheese.

Adapting 3-D printing for food

Three-dimensional printing technology has been around for 30 years, but only in the past few years has it become used widely, in industries such as dentistry, jewelry making and aerospace and engineering. Lipson and his team of engineers, computer scientists, mathematicians and biologists initially provided free access to their first food 3-D printer by open sourcing the directions on how to make one.

Then Lipson heard about a high school girl in Kentucky using a printer to make confections—chocolate and frosting. He initially worked on 3-D food printing as a sideline, researching how to print with pastes and gels, and found that frosting and sugary pastes provided cheap raw materials for experimenting with shapes. But with the advent of 3-D bioprinting (using cells to create human tissue), Lipson realized that 3-D food printing could take off. Because some 3-D printers can now handle multiple materials simultaneously, pastries and other foods can be made in a variety of combinations, shapes and textures geared to individual tastes and dietary needs, such as sugar and salt levels.

Printing food, says Lipson, has turned out to be a lot more complicated than printing plastics or metal. The technology is the same, but the layering of semi-liquid materials is more complex. For one, it takes patience to tinker with the right combination of gels, pastes and powders—the printer “inks”—so that the food tastes good. Another factor is finding a large enough variety of recipes that use only the few basic ingredients available for current 3-D printers.

Aside from chocolate and pastries, Lipson’s group has experimented with printing cheese and pesto to create products like quiche and ravioli. (Depending on the ingredients used, the food may still need to be cooked after it is printed.) In addition, about a dozen research groups globally are experimenting with new ideas in food printing, including more difficult, time-consuming foods such as complex pastries and filled pasta dishes.

The joy of customization

Using a 3-D machine to print food takes more time than preparing food from scratch, so it’s not a good way to make a simple food like a conventional hamburger patty, says Lipson. But it is a good way to customize dishes to different tastes or to accommodate special dietary, medical or health needs. A home cook could easily alter each dinner entree, for example, based on the nutritional needs of various family members.

“Making specially tailored meals is difficult to do manually if you had to actually watch out for all these ingredients and possibly medication,” says Lipson. “That’s a perfect example for using 3-D printing.”

Consumers will “have more control over their food, without requiring all the skill that is involved in being a…good cook, which a lot of people either aren’t or are not interested in being,” says Lipson.

Lipson says he sees a growing market for 3-D home printers in the coming decades because the machines tend to appeal to younger people, who may be more comfortable with computers in the kitchen in general. Another incentive for these generations is the opportunity to incorporate social networking into cooking: “Maybe share a meal with somebody else that’s far away, where you both print the same thing, both print half a pie and eat it together,” says Lipson.

In the future, Lipson anticipates that sophisticated 3-D printing will offer home cooks the ultimate control over the ingredients that go into their food without giving up the convenience of manufactured products.

Related video: Hod Lipson for FutureFood 2050